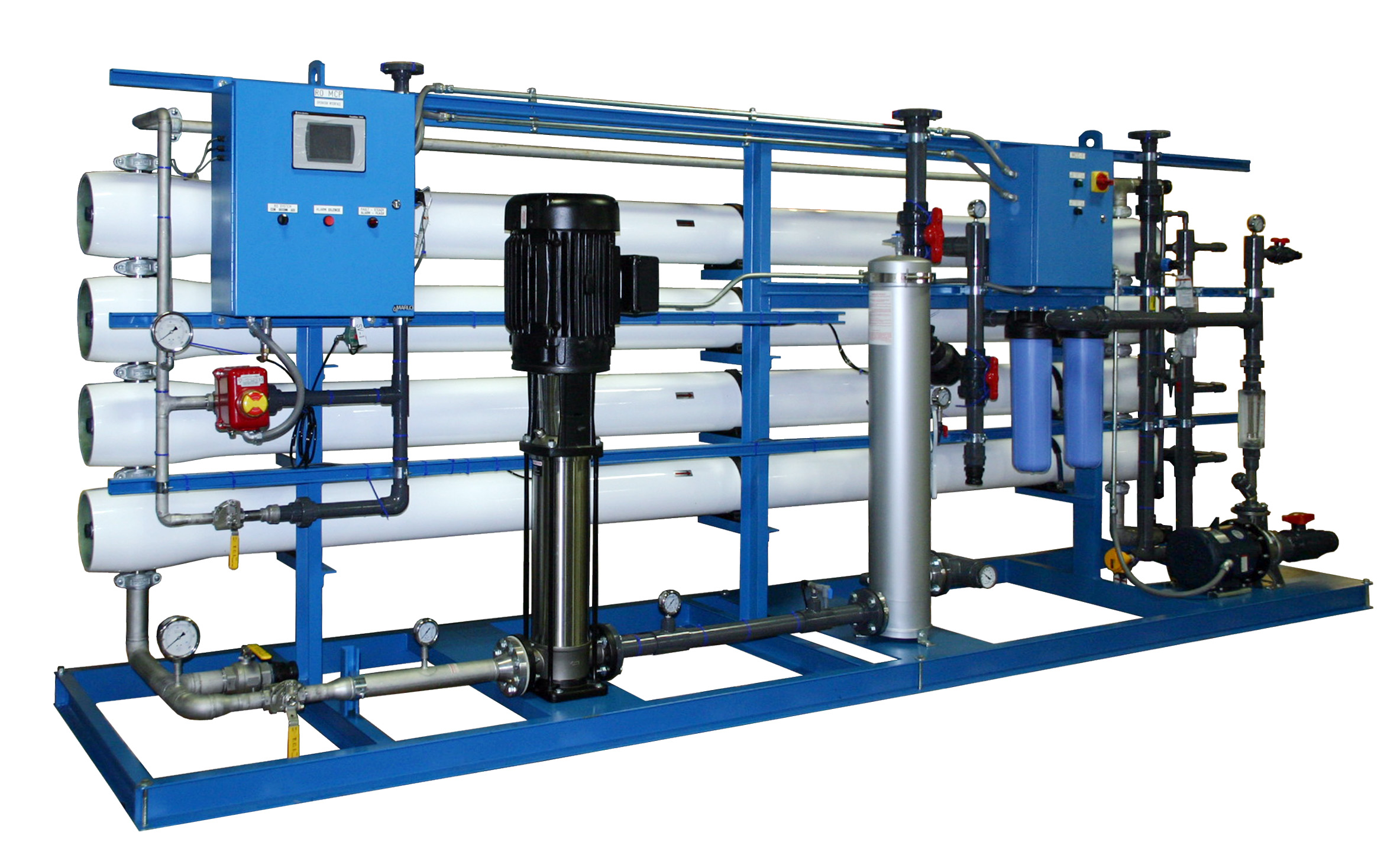

Commertial / industrial R.O plants

Reverse Osmosis is a technology that is used to remove a majority of contaminants from water by pushing the water under pressure through a semi‐permeable membrane. Osmosis is a naturally occurring phenomenon and one of the most important processes in

nature. It is a process where a weaker saline solution will tend to migrate to a strong saline solution. Examples of osmosis are when plant roots absorb water from the soil and our kidneys absorb water from our blood. Reverse

osmosis plants require a variety of pre-treatment techniques including softening, dechlorination, and anti-scalent treatment. Following pre-treatment, high levels of pressure send water through a semi-permeable membrane,

which retains all contaminants but lets pure water pass through. Energy requirements depend on the concentration of salts and contaminants in the influent water; higher concentrations requires more energy to treat. A reverse

osmosis membrane is a semi-permeable membrane that allows the passage of water molecules but not the majority of dissolved salts, organics, bacteria and pyrogens. However, you need to ‘push’ the water through the reverse

osmosis membrane by applying pressure that is greater than the naturally occurring osmotic pressure in order to desalinate (demineralize or deionize) water in the process, allowing pure water through while holding back

a majority of contaminants.

STANDARD FEATURES

• Onboard CIP system

• Touch screen operator interface auto purge on shutdown

• Stainless steel or epoxy coated carbon steel frame

• Stainless steel pumps

• Low energy membranes

• Pretreatment Interlock

• 5 micron prefilters

• Liquid filled gauges

• PLC controller

o Storage tank level

o Inlet Valve

o Inlet Pressure

o Pump Pressure

o Water Quality

o Feed Pump

o Touch-Screen HMI

o Conductivity & pH (if equipped)

o CIP Pump

o Booster Pump (if equipped)

ADDITIONAL BENEFITS

• Reverse osmosis and nanofiltration membranes are a physical barrier to microbes

• Lower operating cost than other industrial water purification methods

• Portable cleaning/sanitizing

systems

• Low environmental impact and minimal chemical dosage required

• Storage tank holds excess water, acting as a buffer tank